| Number of standard 14"x26" Bags | Weight

@

40 lbs each |

Approx square feet, in profile (12" length x 3" height) | Calculations click here for basic formulasHow many bags

are you going to need?

It depends on how much fill you put in your bags, and what size bags you choose. We'll discuss options further down the page. Quick answer: Let's assume you're using standard 14"x26" bags and filling them about 2/3 way (approx. 40 lbs) as in the table to the left. These will give you tamped (finished) dimensions of approximately 15" (1.25 foot) long,12" wide and 3" high. Multiply your intended wall's width by its height; the total gives you the square footage of that one wall. Refer to the table on the left. A wall 15' wide x 8' high would be 120 square feet. The table indicates you'd need about 500 bags. How it works (alternate method): 1.) Measure the linear width of one of your walls. Each foot & a quarter (15") = 1 bag. A 15 foot-wide wall, divided by 1.25 (the length of a filled & tamped bag) would require about 12 bags butted end-to-end per course. 2.) A 40 lb bag will be about 3" high after tamping, making each course 3" high. Every 4 courses will amount to one vertical foot. If your wall is 8 feet high, you'll need 32 courses. Using this method, the above-described 15'W x 8'H wall will require about 12 bags per course & about 32 courses for a total of 384 bags, which is close to the first method. Figure out the dimensions of your remaining 3 walls, subtract for your doors & windows & you'll have a rough idea of the total number of bags your structure will need. ____________________________

Heavier

bags: Some folks like to fill their 14" x 26"

bags to as much as 60 lbs each. These will have tamped

dimensions of approximately:

The obvious advantage of heavier bags is that you will need fewer bags. The disadvantage is that they're much harder to handle, especially as your walls rise and you're lifting them up over your head to place them. Lighter bags = more bags = less labor. Heavier bags = fewer bags = more labor. Using these tables, you can estimate the number of 60 lb bags you'll need by halving the bag count in the column to the left. The same 15' W x 8" H wall mentioned above would require 10 bags per course (at 18" long) and only 24 courses, for a total of about 240 bags. In all cases, regardless of how much fill you put in them, 14"x26" bags will pretty much remain 12" wide (meaning your walls will be about a foot thick, before plastering), We carry larger bags (18"x30" but at 75-90 lbs each, they're pretty hard for most people to handle. Consistency: It'll be to your advantage to fill your bags as consistently as possible to keep your courses straight & to streamline your production with assembly-line precision (see our Techniques page). Sure, you can be organic and free-form (eyeballing the filled bag, guessing at the weight), but you risk introducing small errors that can grow exponentially, and you also risk work slowdowns caused by futzing around. Linear projects (walls, etc.)Calculating

how many bags you'll need for something like a wall is to

simply figure how many square feet the face of the

construction will be (H x L). A very basic rule of thumb

is 4:1 - four bags for every square foot.

Take, for

example, a wall 5 feet high by 10 feet long. Your area

would be 5' x 10' = 50 sq. feet.

Taking this figure, you can do one of 3 things:

Round structuresIf you're

considering building something curved or circular,

then calculating how many 12" long filled bags you'll need

will start with this formula:

d *

pi = number

of bags

where

d=diameter and pi

= 3.14. Multiplying these will give you your

circumference. Since 30 pound bags are 1 ft long, this

figure will give you your approximate per-course bag

count. (A "course" = a single horizontal row.) If you're

using 60 lb. bags (18" long or 1.5 feet long), then you'll

need to divide your circumference by 1.5 to arrive at the

number of bags needed.

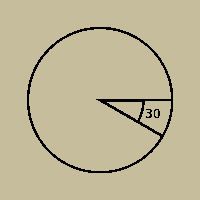

A 10-foot diameter round structure will have a circumference of 31.4 feet. You'll need 31.4 thirty-pound bags. For 60-pound bags, you'll need to divide 31.4 by 1.5 to arrive at 20.9 (21) filled bags per course. As to height: if your tamped bags are 3" high, you'll need four courses for one vertical foot of wall height. So 8 foot high walls, will require 32 courses of 31.4 bags per course = 1005 bags. (Fewer bags, of course, if you're planning on having doors or windows.) 60-pound bags (4" high, 3 courses per vertical foot) will require 24 courses, so 24 x 21 = 504 bags. Establish whether your diameter is inner or outer; it'll make a difference, considering that your walls are about 14" thick after plastering. You can lay out & control your circles & arcs by driving a pin or pole in the center of your building site, and then using either string or a lightweight pole as a pivoting compass. Again, if you're filling your own bags to different dimensions (or using different sized bags), you may have to make corresponding changes to the formulas provided. Arcs and sectors

It also might be helpful to know how to calculate the arc

or sector

of a circle. An arc is a segment of the circumference -

you'd use this to, say, figure the width of a doorway or a

window. A sector is a pie-shaped chunk of the circle

starting at the center and going out to the circumference.

It can be defined by its angle. |

| 1 bag | 40 lbs. | 0.25 sq ft. | |

| 2 bags | 80 lbs. | 0.5 sq ft. | |

| 3 bags | 120 lbs. | .75 sq ft. | |

| 4 bags | 160 lbs. | 1 sq ft. | |

| 5 bags | 200 lbs. | 1.25 sq ft. | |

| 6 bags | 240 lbs. | 1.5 sq ft. | |

| 7 bags | 280 lbs. | 1.75 sq ft. | |

| 8 bags | 320 lbs. | 2 sq ft. | |

| 9 bags | 360 lbs. | 2.25 sq ft. | |

| 10 bags | 400 lbs. | 2.5 sq ft. | |

| 20 bags | 800 lbs. | 5 sq ft. | |

| 40 bags | 1600 lbs. | 10 sq ft. | |

| 60 bags | 2400 lbs. | 15 sq ft. | |

| 80 bags | 3200 lbs. | 20 sq ft. | |

| 100 bags | 4000 lbs / 2 tons | 25 sq ft. | |

| 200 bags | 8000 lbs / 4 tons | 50 sq ft. | |

| 400 bags | 16,000 lbs / 8 tons | 100 sq ft. | |

| 600 bags | 24,000 lbs / 12 tons | 150 sq ft. | |

| 800 bags | 32,000 lbs / 16 tons | 200 sq ft. | |

| 1,000 bags | 40,000 lbs / 20 tons | 250 sq ft. | |

| 1200 bags | 48,000 lbs / 24 tons | 300 sq ft. | |

| 1400 bags | 56,000 lbs / 28 tons | 350 sq ft. | |

| 1600 bags | 64,000 lbs / 32 tons | 400 sq ft. | |

| 1800 bags | 72,000 lbs / 36 tons | 450 sq ft. | |

| 2000 bags | 80,000 lbs / 40 tons | 500 sq ft. | |

| 4000 bags | 160,000 lbs / 80 tons | 1000 sq ft. | |

| 6000 bags | 240,000 lbs / 120 tons | 1500 sq ft. | |

| 8000 bags | 320,000 lbs / 160 tons | 2000 sq ft. | |

| 10,000 bags | 400,000 lbs / 200 tons | 2500 sq ft. | |

| 12,000 bags | 480,000 lbs / 240 tons | 3000 sq ft. | |

| 14,000 bags | 560,000 lbs / 280 tons | 3500 sq ft. | |

| 16,000 bags | 640,000 lbs / 320 tons | 4000 sq ft. | |

| 18,000 bags | 720,000 lbs / 360 tons | 4500 sq ft. | |

| 20,000 bags | 800,000 lbs / 400 tons | 5000 sq ft. | |

| Number of Bags | Weight @ 30 lbs each (average bag) | Approx square feet (length x height) |